Effluent Separation Systems

For 50 years KESSEL AG has remained in the hands of its founder and now employs over 450 workers who are competent in the field of indoor and outdoor drainage.

Founded in 1963 and headquartered in Lenting, Germany, the KESSEL AG Company is the innovation leader in the development, manufacture and supply of drainage products. With a workforce of over 500 employees and sales partners in over 50 countries worldwide, KESSEL shower drains, grease / fuel separators, backwater valves, pumps and hybrid lifting stations are specified in domestic, commercial and industrial projects around the globe. The products are ‘Made in Germany’ and ‘Made by KESSEL’.

KESSEL is a premium manufacturer of innovative products in the field of drainage technology and pursues ambitious goals of international expansion whilst endeavoring to keep its feet on the ground. They strive to achieve and maintain a leading position in our markets through innovative products of the highest quality. Kessel works meticulously to continuously and permanently improve all areas of the company and regard themselves as an independent organisation that creates and sustains corporate values.To customers they are a reliable, flexible and competent partner, and to their employees Kessel remains a secure and understanding employer.

- Grease Separators

- Oil Separators

- Lifting Stations

- Drains and Channels

- Backflow preventers

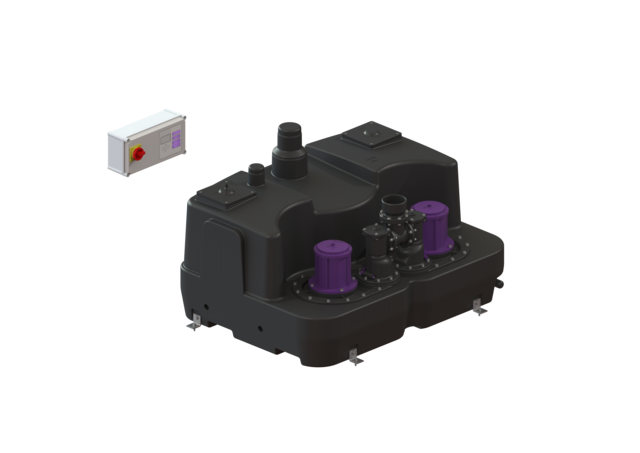

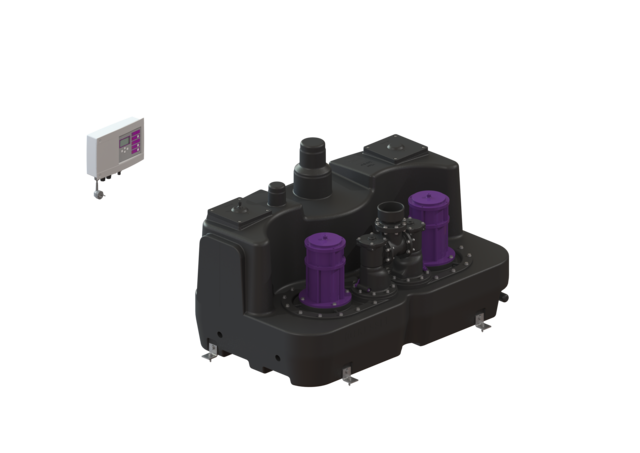

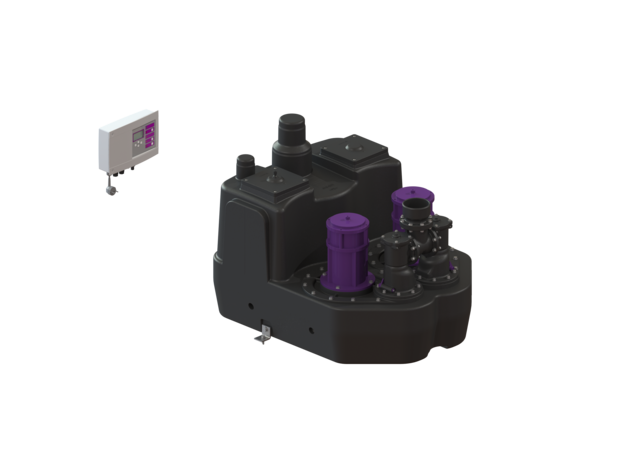

Lifting Stations

Kessel has a range of lifting stations to lift wastewater, where it cannot be drained with gravity, for example : wastewater from services in the basement. Duty / standby pumps with different capacities of polyethylene storage chamber, available in free standing and underground versions, with different capacities of pumps starting from 1 kw single phase to 11kw 3 phase, non chokable or macerator pumps, the range is very widespread to suit the requirements of the Planner or the Project.

Grease Separators

Kessel is in the forefront when it comes to systems that helps in separation of substances from effluents of Kitchens, Abattoirs and Car wash stations. Since water is one of our most precious resources and since it’s not available in unlimited quantities, contaminated wastewater from kitchens must be pre-treated and cleaned with the aid of appropriate separator system before it’s discharged to the public sewer system. Under performing public wastewater treatment facilities leads to additional costs of maintenance and repair. Kessel manufactures fully automated separators according to EN 1825, which gives the end user the ease of operation of disposing off the effluent with absolute zero odor in the premises.

A 100% environmentally friendly system where the separation happens only via the law of gravity. EN 1825 norms doesn’t allow to use any enzymes or chemicals for the separation process. After the arrival of a disposal truck, the contents inside the separator i.e. grease and sludge is macerated / grinded into a pumpable mass and pumped into the disposal truck, rinsing cycle occurs with the help of water which is automatically filled to the required quantity. After the rinsing cycle, the separator is filled up with cold water and it’s ready for it’s normal operation. The ease of use, zero continuous costs like dozing systems, once in a month disposal, no odour and safe way of disposing off grease is the highlight of a Kessel Grease Separator.

Oil / Fuel Separators

The Kessel Oil / Fuel Separators are manufactured according to EN 858. Regulations calls for separating any mineral oils or fuels at source to protect the sewer and the treatment systems of the city. Oil / fuel separators are normally installed in car wash stations or any industrial complexes where such mineral oils can escape into the sewers. EN 858 norms calls for huge sludge capacities to withhold sludge for almost a month, which in return helps in lowering disposal costs. The self actuated closure valve, which is a must within the EN regulations does not allow any of these mineral substances to escape into the network. Both Grease and Oil Separators can be installed with ‘Ultrasonic Control’ that senses the level of the grease and fuel in real time, to give an intimation to the service team for emptying of the separators. Kessel separators are manufactured out of polyethylene and is warrantied for 20 years.

Backwater Protection – Safety Redefined

Backwater damage is a threat to millions of homeowners and builders, and never has the damage caused by flooding and backwater been as costly as today. However, many builders and homeowners remain unaware of the fact that they can and must protect themselves from backwater. Local authorities and insurance companies require such protection. The current climate changes, bringing with them sudden torrential rainfall and flash flooding, especially in the summer months, require timely considerations regarding backwater protection. Professional and suitable backwater protection helps to maintain the value of properties and buildings in the long term. KESSEL is proactive in offering you support in both the clarification and consultation regarding the topic of backwater protection.

With the new premium backwater valve series Staufix SWA, Staufix FKA and Pumpfix F, KESSEL is setting standards in protection against backwater and flooded basements. This means that installation professionals and home owners both profit from a flexible modular system, innovative installation, operation and maintenance solutions and the very highest quality and safety of the KESSEL backwater valves.